The Truth Hurts, Says Indian Navy’s 1st Dhruv Flight Commander

By Commander YASHODHAN MARATHE (Retd.)

I’m a second generation helicopter pilot and have been flying rotary wing machines since 1989. Of course, the primary amount of flying has been on HAL built aircraft, the Chetak and the ALH and of course, the Kiran.

I’m quite saddened by the slew of remarks against a former CNS, himself a decorated pilot. HAL has often taken one or two points in which there may be a slip-up, and highlighted only these points, thereby glossing over the crux of the matter. In this case, the crux of the matter is blade folding, not the “automatic” part that inadvertently came up. I have been in the field at the helm of affairs when the Naval ALH were taken on board the aircraft carrier for the first time. The idea was to test out the helicopter in the role that it was destined for. Sadly, the maiden embarkation on board the carrier was a challenge that the helicopter could not live up to.

Blade folding is a major sticking point that is currently being discussed. The navy had specified to HAL the requirement of a 3.5 m blade-folded width right from the very start. This was based on the shipborne requirements because, after all, the helicopter would have to land on a ship and be stowed in the hangar after folding the blades. At sea the requirement is also for a quick and easy way of folding the blades. Just like the Chetak or the Kamov, or the Sea King. Logically then, HAL should have thought about this as a major design shortcoming before even offering a helicopter with any width greater than 3.5 m. The navy had contributed a fair amount of money towards the development of the indigenous helicopter, yet it is quite clear that the blade folding requirement was not given its importance even during basic design at HAL. The navy as usual was forced to accept the initial lot of helicopters under concession.

It is always the crew that are pressurised to support ‘indigenous effort’ and were as usual told to at least

start flying the helicopter and gain some experience. This was for the first 8 helicopters. Today, this very acceptance of a concession is being turned around to twist the Navy’s tail by making statements like the navy and HAL should sit together to discuss these points and engage HAL to let them know what the navy wants.

As a solution about fifteen years back, HAL had made the suggestion that the Navy should accept the method where one blade remains forward and other three go back. For this, HAL actually suggested that the Navy should cut holes in the helicopter hangar for the front facing blade – classic case of making the hand fit the glove. The thing is, these suggestions are often made at the MoD level, and the impression given is that the Navy is adamant in not taking this option. Similarly, the concession given to HAL was to achieve a 5.4 m folded width to begin with, instead of 3.5 m. They could not meet even this 5.4 m, and the constant complaint in any forum was that navy cannot accept even 0.2 m more than the required width – conveniently forgetting that the 0.2 m was from the 5.4 m, not the original requirement of 3.5m.

The problem in all this is that the person on the top does not have the background and the time to understand the nuances and gets convinced that the navy is putting unreasonable demands. The segmented blade folding option was discussed way back in 2005-06, so there is no reason that HAL should not already have done this over the last fifteen years if they were serious. At that time HAL had wanted the Navy to sponsor the study and trials. There is nothing new in segmented blade folding. The Chetak has got a two-piece blade from 1960 onward. Retrofitting the ALH for segmented blade folding will not only increase weight, but should also involve hundreds of hours of testing. And I’m not sure whether to trust the results of these flight tests, given the efficacy of the rigorous testing that HAL does.

To give everyone a clear viewpoint of the blade folding procedure, there were a total of 64 loose items that had to be removed, used, fitted back at the time the kit was offered in 2005. This took over half an hour, though a timing of 22 minutes or so was demonstrated using five HAL personnel and safely on ground with no wind and no rolling and pitching of the deck. I can’t imagine five personnel being employed for folding the blade in a procedure that takes over 20 minutes. During folding on board the carrier the first helicopter became unserviceable because the lining on the blade came off as soon as we folded and put back the blades. On the second aircraft, the bolt broke. HAL will claim that they have rectified this, by putting the lining on the bolt and using a better material of the bolt. They also would have reduced the number of items. But the procedure still takes too long, and at sea, this becomes a danger from submarines to the ship which has to maintain a steady course.

To come back to the point, the biggest problem again here is that the customer which is the Indian Navy, was given a product that did not fit the bill. Once again fault is being found with the Indian Navy for not supporting indigenous development. And the crux of the matter is being diverted by focusing the attention on the term ‘automatic blade folding’ that wasn’t asked for, only a convenient and quick blade folding.

Let us go to the testing philosophy of HAL, that many of crew felt was suspect. The (in) famous crash of the first civilian Dhruv after takeoff from Hyderabad was completely avoidable. For those of you who may not remember, the Government of Jharkhand ALH while on ferry from Hyderabad to Ranchi, lost the tail rotor at cruising altitude, and had to force-land. The aircraft was a writeoff, but the crew survived.

Before emphasising the survivability of the ALH, I’d like to point out that this failure occurred in cruise, at normal forward speed, and there was more than enough time for emergency actions, by the experienced test pilot that was flying the helicopter. If this had happened at hover, it was certain death. Now, a few months before this while ferrying a naval ALH to Visakhapatnam, the tail rotor gearbox had sheared off, and was hanging on just two supports. We could see the entire rotor disc shaking vigorously at hover, and it was quite scary. After landing, it was with horror that the crew found a nearly 8-inch portion of the tail rotor blade leading edge had flown off. This imbalance caused excessive vibrations and damage to the tail gear box. Another few minutes and this tail rotor would have flown off too.

This was a serious matter, and taken up with HAL. They provided the simplistic solution of changing the tail rotor blades and the tail gear box on board the ship, and expected the crew to fly the helicopter as if nothing had happened. When questioned about the analysis and the steps taken to prevent recurrence, the HAL staff were surprised why we were questioning their superior method of addressing the problem. To them the defective item had been replaced with another one, and voila! Good to go.

When we asked them about a similar thing happening on the new tail rotor, the answer was, “We have tested this and it is okay”. Well, the one that broke also was tested, right? In all this, we found that one more helicopter tail gearbox had a crack in a similar place (two down out of only three on board the ship). HAL remained unfazed, and claimed that the two cracks were unrelated, and other helicopter gearbox had cracked due to “over-shimming” so we were not to bother. They would replace the other gearbox too. Nice solution. Over-shimming -This had obviously been done at manufacturer facility. Why was not the person responsible for this over-shimming brought to task? If it were found that a Naval technician had missed out something important, there would be some disciplinary action if it was negligence, and a method of addressing the issue if it was procedural. Not sure if the person who signed off on the paper clearing that helicopter for flight was taken to task or not.

At this point, HAL should have done a proper analysis of the cause and taken corrective actions of the tail rotor blade debonding. If they had done the study, then possibly the crash of the ill-fated civilian ALH on ferry from Hyderabad to Ranchi in November that year, would have been avoided. This is a clear case of, well, so many things. There were many other findings that came as a result of this accident. A peculiar one was that the CVR/FDR stopped recording after both engines were shut down. The simple fact of ensuring that the vital black box is connected to the battery when both engines were shut down had been missed out during design. So, when the generators stopped working, so did the crucial recording device. We all keep wondering what other crucial things had been missed out by design.

I’m not sure of the actual effect any disciplinary action taken after the crash of the first civilian ALH because there were many problems found in the processes being followed in manufacture of the blades. Among them, the process of manufacture of the composite tail rotor blades. The entire fleet was grounded for six to eight months until we got replacement blades. Again, these blades started showing signs of cracking up of the resin coating. HAL said it was not a problem. Photographs are scary.

There have been a few crashes on the ALH in the recent past. Two Army aviators lost their lives and in the latest one, the Army Commander was on board, when a critical component in the control chain failed. This kind of failure is unheard of in any modern helicopter, and puts a cloud on the whether the testing of any modifications is really exhaustive or just that there is some aspect missed out either by ignorance of act of omission. I do not want to elaborate further, because the cause is not yet finalised, but so many crashes in such a short time do bring about a very big trust deficit.

After this embarkation on board the aircraft carrier, there was a detailed analysis carried out internally and it was fairly well concluded that this helicopter would not meet the exacting requirements of Naval flying from ships, and the problem areas were highlighted to HAL.

Well before we embarked the carrier, we had to contend with many other issues. The strangest one was that whenever it rained, it poured inside the cockpit. Water would come through the overhead CB panel, and pour on the collective pitch where the engine control was located. Water would drip on the instrument panel. Water would drip on the passenger seats. I remember the AME of the civilian Dhruv telling me that the ONGC Chairman when flying on board the civilian ALH once had to use a newspaper to shield himself from rain. HAL will again claim that this point has been addressed. But the main issue again begs question, why was this not checked out in design and before delivery?

As far as the Indian Navy went, we were the most problematic customers for HAL. We would demand that the helicopter be fully free from any rain water leakage, we would insist that all the documentation had to be in order, and that all instruments had to be fully functional before we left the facility. We would make sure that there was no defect on the helicopter before leaving for the unit. The crew were very sure that once we took off from the helipad to take the helicopter back, we would get no support from HAL. The advantage of the Navy was that our sailors and officers had worked with Western technologies for a very long time with the Sea King, the Sea Harrier etc. The procedures laid out from so many years of following internationally laid down standards in acceptance procedures made the Navy a very painful customer for HAL. HAL may state that they have addressed many of these problems in the Mark 3, but why should the problem been there in the first place? Would you accept a car from the dealer that leaks rain water? HAL designers and others at the plant would often claim that this was the first time they were making a helicopter, so there would be some ups and downs. This excuse even then was completely untenable, because HAL as an organisation manufactured everything from spacecraft components and supersonic fighters to propeller trainers. this is not because HAL is the best, but because nobody else has been permitted to do this. There is no bigger tragedy for the nation than not allowing any competition. Ask any Services pilot and you will hear the truth – the finished aircraft lack quality, HAL lacks commitment and most of all an unwillingness to face the truth. I’ve rarely if at all heard anything good being said about the HAL. If this is indeed the case, why is it that the opinion of the real customer never taken, the pilot in the field?

The real question to ask is that if HAL is indeed so capable and the ALH is really a world-class helicopter why is it that there are no sales in the civil market and for Military Export? The issue seems to be that HAL has set its standards very low by any yardstick, and it reminds me of the saying that goes “ the real problem is not that I will set my standards too high and fail, but that I will set the standards too low and succeed”. Successive HAL products have been pushed down the throats of the reluctant Armed Forces, and they are in no position to refuse – unwilling customers that cannot say no, for various reasons. The correct thing to do for HAL would be to challenge the globally established players; prove that the helicopter and the Company is right up there along with the best. This in itself will ensure that the Services come willingly to the table to buy the ALH for their own use.

Following the 2007 crash of IAF’s helicopter display team’s Dhruv, a Comptroller and Auditor General (CAG) report from 2010 highlighted the fractured relationship between HAL and the IAF. The report blamed HAL of compromising with professionalism to protect its business interests, which in turn could have serious implications on safety of the people flying and operating the machine. The report also highlighted the problem of “cyclic saturation” with the helicopters, which caused two of the crashes (including the one in 2007). This technical oversight had also reportedly cost HAL a contract with Chile for the sale of the helicopters.

I also perceived a lack of professionalism at HAL. To list out some:

During acceptances at HAL, we would find that individual components would have been switched from other helicopters. In other words, the log card would state that for eg, the fuel pump serial no 12345 was installed, but the actual item on the aircraft would be serial no 98765. Once we realised this, then it became de-rigueur to physically inspect each and every component to check that the component is correct. HAL were concerned about this, and would say, why are you so fussy? Why is this so important, you may ask. It’s important because each component has certain flying hours and a defect history that is recorded in the log card, and ensures that nothing which is defective or with more flying hours on it than recorded is installed. Would you ever think of doing something like this from any foreign vendor? One expects a certain level of integrity and honesty from any vendor, especially a PSU that is supposed to be trustworthy.

The Final assembly line of the helicopter used to be very bad. There was no proper hygiene maintained. For eg, all the metal filings from the drilled holes would fall to the aircraft floor, never to be cleared. There was no template being used for the drilling of holes, so each panel had to be hand-crafted because there was nothing standardised. I have personally seen people working on the open Main Gearbox / IDS with tools and pens sticking out of pockets. Anything could fall out of the pocket into the gearbox, causing dents and leakages. We have removed ballpoint pens and nuts / bolts under the floor board, in the area of the floatation gear bottles after hours of flying. A very dangerous incident was when we had sparking and melting of the alternator cables. Never heard of. The HAL solution was to replace the cables. All was well, and the team that had come with the cable, told our engineer, that the cable was too long, and they wanted to use tiewraps (or tie-wire) to secure it. Fortunately for us, the designer also came by that day to find out what was wrong. He was horrified to find that the persons installing the new cable did not have a wiring diagram, and had routed the cables incorrectly. This was the reason there was ‘extra’ cable. We were saved a repeat of this. There were so many places all over the aircraft where cable bundles were secured with a tiewrap due to which the cables got cut. This was because of the vibrations on the aircraft, and the cables likely not being routed correctly. It is likely that many of these are corrected, so I will not dwell too long on these points, but such lack of basic engineering hygiene and procedures invariably led to many failures. This is completely unacceptable from any standpoint in a manufacturing company that specialises in Aerospace components and aircraft.

One day we came back from a sortie during which we noticed the GPS position not showing. On return, we found that both the GPS antennae had flown off. When I called HAL, I was horrified when I was told that we were not the only ones – so why didn’t they tell us in time? This meant that they knew this was happening. It was a faulty design of the antenna mounting bracket and we found cracks on all of them on other helicopters.

While I can go on about individual incidents, the crucial point is the way that HAL handles any defect reported by the customer.

- There seems to be very little accountability. When the customer reports a problem especially grave problems, the manufacturer must find out the deeper reason for the defect or failure. In Mathematics, it is called ‘deriving from first principles’. The manufacturing process has to be vetted. There could be a flaw in the assembly line, or there could be a problem with the particular tooling used to put together the component. Or there could be just plain carelessness. Like in the case of the alternator wire. While punitive action may not be always necessary, some amount of disciplining is required. As customers, the Service pilots never get to know whether the root cause has been addressed – all that we used to receive was a defect summary that did not tell us what exactly has been done.

- The way HAL handles most defects is replacement, without really going into the root of the problem. The tail rotor issue on the ALH is one example, that I have written about. I was not satisfied with the resolution of the problem, and refused to fly the helicopter from the Carrier at the time.

The other point is about the way that the design bureau looks at designing a helicopter. A couple of examples are in order. The engine cowlings on any helicopter are designed to open upwards, sometimes they open downwards so that people can stand on the cowlings and work on the engines. Not for ALH. The initial design required two technicians to climb on a huge platform and open about a dozen and half fasteners, and then the entire cowling had to be taken down like an egg-shell and laid on the ground. It was only after many meetings with the Navy, that HAL agreed to cowlings with hinged clamshells that would open downwards providing a platform for the worker to stand on. The quality of these clamshells was so bad, that they would bend and break at times. This point will also possibly be refuted by HAL as having been addressed, but the issue is that this should not have happened in the first place at the time.

I actually casually asked some of the designers whether they had ever worked on, or closely studied any other existing type of helicopter, to see the crucial design issues and other small modifications or attention to detail they had done. “No” was the answer. They seemed genuinely surprised about my asking and proudly said all of them were PGs, with some either holding or pursuing Doctorates, (so why would anyone want them to look at other helicopters). My point was also important because it is only when you have physically worked on any helicopter in the field, will you understand the day to day problems with regard to accessibility, Human-Machine Interface (HMI) issues and the like. They will would also see how other manufacturers have addressed issues that they may have faced. Many of these are simple solutions, may not be patented and can easily be adopted. One simple example is of the hand holds provided to climb on the engine deck. The HAL has provided handles made like similar to commercial cupboard door handles, sticking out into the airflow. Other manufacturers have provided spring-loaded flaps, so that the flap goes in when you put your hand or foot, and the flap provides a smooth finish to reduce drag in flight. Even these door type handles were so badly made, that one of them broke when a sailor was climbing on top, and broke his hand. We are fortunate he was alive. What happens if he falls overboard? I’m sure HAL would have then provided a heavier hand hold, and come up with some theory that the person should be more careful when climbing up or something like that, rather than addressing the core issue. Other manufacturers have provided spring-loaded flaps, so that the flap goes in when you put your hand or foot, and the flap provides a smooth finish to reduce drag in flight. It must be understood that all most of the other manufacturers worldwide have adequate staff on the design and production that who have a lot of experience in the field, and therefore know and understand the problems faced by the man in the heat of the battle when tasked to service and to fly the helicopter.

Another point is that there is no independent thought or foresight. A simple example – I also asked one of those on the LUH design team in the Design Bureau, whether they had considered commonality of parts between the ALH and the LUH. Again, they were surprised, and asked me why is this relevant? Now, if I need to answer that question here in this article, then evidently, the reader has no authority to comment on anything written here.

Coming back to the issue of customer base, the LUH could have been developed and matured in the civil market, and then offered to the Services, if HAL were so confident that the product was good. It must be realised that the civil world has no time to waste in down time of aircraft. Time is money, and they cannot afford the luxury of down time like the Services have to. Penalties are extremely harsh, and could even be up to a lakh of rupees per half hour of delay in positioning of the helicopter. ONGC and all Oil Companies impose such penalties on the helicopter companies. I myself was working on a contract where the only down time permitted for the single helicopter was 48 hours in a month, non-cumulative. Can

anyone be confident of providing such a commitment were he to operate the ALH?

All pilots will have personal instances of an lackadaisical indifferent attitude or a deliberate wrong being done at the factory, just to get the aircraft off their backs. Our unit once took three months to accept a helicopter from HAL. This delay was because of recurrent problems with vibrations, rain water leakage, components not matching, the list is endless- but we didn’t budge. Can you think of any other manufacturer that will take so long to deliver a helicopter that has only just come out of servicing?

Before we go too deep into the how and whether HAL should be considered to provide the Navy with the 111 helicopters needed to replace the Chetak, we should first consider the current state of our Military-Industrial-Complex. A large part of the income from exports of any major industrialised nations comes from weapons / systems sales. India has practically none that really matter.

Incidentally, ALH helicopters were sent to Nepal, Israel and Equador. The HAL crew really put in a lot of efforts for preparing the first of the civil helicopters to be sent abroad to Israel, in 2005 or 2006. A lot of efforts meant they did a very good paint job. I’m not sure if the rainwater leakage was fixed or not, but the difference in the quality of paint job between that helicopter and the one they had prepared for the Navy was enormous. Just like the “Export Quality” goods that used to be advertised in India. The HAL had a marketing contract with an Israeli firm, which nobody is talking about. If the ALH was indeed manna from heaven, then why did this marketing contract not produce the desired results? Israel promptly returned the civil registration helicopter and this is never mentioned anywhere by HAL. I’m not sure if Nepal is still flying their ALH. Ecuador has

grounded all their remaining helicopters after some of them crashed, one quite spectacularly during a parade and cancelled the contract. HAL claims this is pilot error, and the customer thinks otherwise. In any case there was a trust deficit and Ecuador cancelled the contract, mainly, because

they were at liberty to do so, unlike the Indian Armed Forces. HAL had exported one ALH on contract to Israel which they returned to HAL because they didn’t find it good enough. This and the aircraft sold to Equador most of which crashed is not even a drop in the ocean of defence sales. The ALH with Nepal and Maldives were

gifted by the Government of India, not purchased by them out of choice.

The Defence Procurement Procedure (DPP) in many ways tries to address this shortcoming of the Military-Industrial-Complex. It is clearly stated in the preamble that “A need has also been felt for identifying strategic partners for promoting defence production in the private sector.” To start with, this one definitive push is in the right direction. A private sector player is interested primarily in the bottom-lines. This statement should not be quoted out of context. This is because even the PSUs are required to adhere to budgets, time lines, and finally, generate profits. The approach to this is different for both of these. Private industry will not compromise on quality of intake, or have to go through detailed procedures and governmental approvals to achieve the desired results. To quote some examples from the non-aviation commercial space, an excellent example is what happened to Maruti, after collaboration with Suzuki, and what was the status of Maruti Motors before that. Prior to this, India was ‘atmanirbhar’ for cars like the Ambassador Mark 4, the Premier Padmini and the Standard Herald. The fact that these were copies is a different matter. The common man had to be happy with the paddle shift gears in cars. The electricals were so bad that batteries had to be disconnected when going out of station. Cars needed petrol to be poured over the carburettor on a winter morning to start. I myself have driven a Premier Padmini and the change from this to a Wagon R was like moving on to a completely different level. Remember how all of us had to tilt our Bajaj Chetak scooters before starting? Do we do this with any of our modern bikes, whether an indigenous bike like the Pulsar or a foreign one like a Honda Activa?

Why I bring these examples to an aviation discussion is that the basic principles are the same – India had a practically non-existent industrial capability and never seen or used modern manufacturing techniques, better standards of equipment and the highest safety standards. Do any one of you think for a moment, that if the Government of that time had not brought in Suzuki, we would have been driving anything other than the Ambassador or Padmini? There is a dynamic difference in the machining, finishing, quality of workmanship and performance of the modern generation cars. Perhaps India would have had a much larger share of global manufacturing of cars, had the Government gone all the way, and allowed more numbers of car manufacturers to set up base here. However if other manufacturers had been allowed a free run like Maruti was, then Maruti may not have had the lion’s share of the market today. A similar mindset we’re seeing now about the HAL’s entry into the NUH market, existed in 1982 when Suzuki was brought in. In the case of the NUH debate, seems to be a feeling that if another manufacturer comes into India and proves its mettle, then the unchallenged position of HAL will be in danger. If we do not grab this opportunity of tying up with a foreign manufacturer, to set up shop in India, with a

Private entity, then we will definitely miss the bus to building a strong Military-Industrial-Complex.

I’m a commercial helicopter pilot now, and wish to touch upon the issue of speed. Why is speed so crucial you may ask? Well, to cover a distance of 100 NM (Nautical Miles) a helicopter flying at 150 kts will take 40 minutes, and the ALH zipping along at 110 kts will take about 15 minutes extra. So what’s the big deal? Imagine YOU are the person drowning in the water, fighting to stay afloat, and have to wait for 15 minutes more. Or, you need to reach the point where the enemy submarine is so that you can speedily drop the torpedo before the submarine disappears. Additionally, since the fuel consumption figures of the S76 and ALH are comparable, the same amount of fuel will just take us that of a much lesser distance in an ALH.

The fact that the Naval version of the ALH is about 400 kg heavier than the IAF/Army version is another point to be kept in mind. This difference is as good as 5 passengers and is a crucial point. Weight increase has also been caused by the imported Vibration damping equipment strapped on at a later stage, which should not have been needed to start with, but that is a different line of discussion altogether.

If HAL was truly serious about providing a naval helicopter, the moment design bureau realised that 3.5m width wasn’t possible, a possible decision could have been taken at the time that the basic airframe could be the same, but the rotor head and blades for the Navy would be optimised for sea level operations and shipborne use. The current ALH is more optimised for high altitude use and survive battle damage, and hence separating the two designs could have yielded the required results. The Sea King is excellent for sea level use, but cannot cross the Banihal pass. Similarly, the ALH performs admirably at high altitudes, but the same performance could be a drag at sea level (pun intended). This option is just one of the possible scenarios I’m suggesting, in hindsight of course. If this was not considered possible, HAL should have at the onset accepted that that they will not design a helicopter for the more exacting Naval requirements. HAL claiming (as per information on a different website) that the cost of an imported helicopter would cost 10-15 crores more without actually knowing the figures is incorrect. We don’t even know the exact cost of an ALH.

Coming back to the ALH, the moot question is – how much of the ALH is actually Indian? The engines are ‘manufactured’ at the HAL Engine Division, a euphemism for assembled. The Avionics are Israeli. Crew seats are imported, as are passenger seats for VIP. The material used to make the airframe and blade comes from various sources abroad. There is enough literature about the weapons that are going to be imported. Floation gear is imported. The Rotor brake was made in India with quality control by HAL. These brakes used to suddenly get jammed while flying, and so HAL said to us, fly without the brakes. Sadly with this aircraft, the Sum is less than the Total of the parts.

Coming to the oft-repeated term of indigenisation. When we speak of an Indigenous product, what exactly is indigenous? Something produced by a PSU (with parts from all over the globe) or something that is produced in India, even if it is by a foreign manufacturer with imported and locally produced parts. By different yardsticks, a Hyundai car made in India will be indigenous or will be imported. It is the same for home use items like Surf Excel or Colgate. Should we stop using any of these products? There are enough clarifications in the news from the Government that an item manufactured by a multi-national company in India will still be considered Indian / indigenous. So we have to understand that if a foreign vendor with years of experience comes into India to set up shop to manufacture a helicopter, he is bound to bring with him the expertise, the precision manufacturing practices, industrial safety and everything that has made that company successful. You are automatically creating a value chain, supply chain that will increase the standards of manufacturing and design in India. This will also spawn its own network of MSMEs and design experts. This will further spur indigenous R & D and design as well as spinoff manufacturing. This is just like the previously described automobile revolution.

Today there are Indian companies producing world class components for foreign manufacturers. I was told at the Sikorsky factory that the entire cabin structure of the S92 is manufactured in India and sent across. This is the norm everywhere. An American helicopter can have French engines, or Canadian engines, European manufacturers will use engines from Pratt and Whitney, components from all over the globe, so in that sense, any helicopter is a fusion of material from around the globe. What then is different if HAL does the same thing? Sadly with the ALH, the sum is less than the total of the parts.

What can HAL however, bring to the table? If we allow a foreign vendor to bring in a helicopter that is suited for the Naval requirements, then ultimately, the Nation will benefit. If we were to insist on HAL’s (unsuitable) helicopter being inducted into the Navy to replace the Chetak, then we are doing a great disservice to the Service and to the Nation. I do not understand why there are so many demands that only a PSU should make helicopters and that the design effort of HAL should not be allowed to go waste. If as I’ve said earlier, the product is really so good, there will automatically be a queue to purchase the helicopter. HAL has its order books full not with willing customers, but with those that had no choice. The navy today has a choice and there seems to be a determined move to scuttle this choice. If the ALH were to be imposed onto the navy as the NUH, HAL may have won the NUH battle, but we India will surely lose the war. We in addition would have lost an opportunity to break free of the clutches of the Soviet era mentality that believed anything made or done by the government is good, and anything done by private enterprise is evil. We would have forever killed any opportunity of nurturing real talent, as well as allowing knowledge and skills to grow and flourish, all for short term gains of a PSU that really, has nothing to gain or lose from the contract, other than a sense of prestige and balancing of the account books.

When we look back many years later, we will then know exactly on whose door to pin our failure as a nation to seize the moment.

The author is a 55 year old helicopter pilot, Qualified Flight Instructor and has about 5800 hours of flying. He was the Flight Commander of the first Naval ALH flight and has adequate experience in taking the ALH through all the paces required for Naval requirements. After retiring from the Navy in 2008, he has flown commercial offshore and ashore flights. His views are personal.

The Truth Hurts, Says Indian Navy’s 1st Dhruv Flight Commander

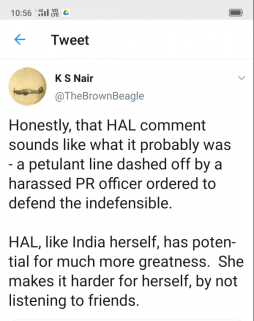

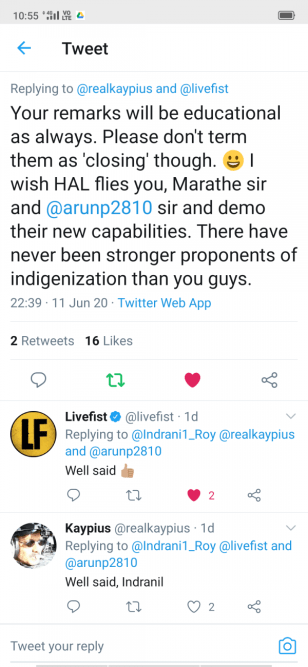

Wonderful writeup by the commander. Settles most of the questions.