Chhattisgarh to get semiconductor plant; GaN chips to power 5G, 6G from Nava Raipur

PTI

Last Updated: Apr 10, 2025, 07:35:00 PM IST

Chhattisgarh Chief Minister Vishnu Deo Sai will lay the foundation stone for the country's first Gallium Nitride (GaN)-based semiconductor manufacturing unit in Nava Raipur on April 11. With an investment of Rs 1,143 crore, the project will place Chhattisgarh at the forefront of the global semiconductor industry, officials said.

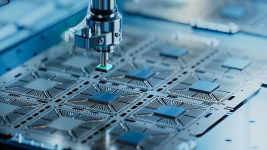

The chips produced at the factory will just not power everyday devices, they will fuel the future, enabling next gen 5G and 6G networks, high-performance laptops, defence technologies, data analytics, and cutting-edge power electronics.

The state-of-the-art facility will be developed by Chennai-based Polymatech Electronics, with an ambitious production target of 10 billion chips annually by 2030. The plant's establishment marks a crucial step in India's drive to reduce its dependency on semiconductor imports and bolster its position as a global tech powerhouse.

Speaking on the development, Rajat Kumar, Secretary, Chhattisgarh Commerce and Industry Department, said, "This partnership with Polymatech will transform Chhattisgarh into a global hub for tech innovation. Investor-friendly policies, world-class infrastructure, and fast-track decision-making are turning this vision into reality".

Calling it a historic milestone for Chhattisgarh, Sai said, "Chhattisgarh is now poised to shine on the semiconductor map. This project is a major stride towards fulfilling the vision of Make in India and Digital India".

Globally, Gallium Nitride (GaN) is being seen as a game-changer in the semiconductor world. GaN chips are faster, more energy-efficient, and highly durable, making them the ideal choice for next-gen technologies.

Chhattisgarh to get semiconductor plant; GaN chips to power 5G, 6G from Nava Raipur

PTI

Last Updated: Apr 10, 2025, 07:35:00 PM IST

Synopsis

The chips produced at the factory will just not power everyday devices, they will fuel the future, enabling next gen 5G and 6G networks, high-performance laptops, defence technologies, data analytics, and cutting-edge power electronics.

The chips produced at the factory will just not power everyday devices, they will fuel the future, enabling next gen 5G and 6G networks, high-performance laptops, defence technologies, data analytics, and cutting-edge power electronics.

Chhattisgarh Chief Minister Vishnu Deo Sai will lay the foundation stone for the country's first Gallium Nitride (GaN)-based semiconductor manufacturing unit in Nava Raipur on April 11. With an investment of Rs 1,143 crore, the project will place Chhattisgarh at the forefront of the global semiconductor industry, officials said.

The chips produced at the factory will just not power everyday devices, they will fuel the future, enabling next gen 5G and 6G networks, high-performance laptops, defence technologies, data analytics, and cutting-edge power electronics.

The state-of-the-art facility will be developed by Chennai-based Polymatech Electronics, with an ambitious production target of 10 billion chips annually by 2030. The plant's establishment marks a crucial step in India's drive to reduce its dependency on semiconductor imports and bolster its position as a global tech powerhouse.

Speaking on the development, Rajat Kumar, Secretary, Chhattisgarh Commerce and Industry Department, said, "This partnership with Polymatech will transform Chhattisgarh into a global hub for tech innovation. Investor-friendly policies, world-class infrastructure, and fast-track decision-making are turning this vision into reality".

Calling it a historic milestone for Chhattisgarh, Sai said, "Chhattisgarh is now poised to shine on the semiconductor map. This project is a major stride towards fulfilling the vision of Make in India and Digital India".

Globally, Gallium Nitride (GaN) is being seen as a game-changer in the semiconductor world. GaN chips are faster, more energy-efficient, and highly durable, making them the ideal choice for next-gen technologies.

Chhattisgarh to get semiconductor plant; GaN chips to power 5G, 6G from Nava Raipur