DRDO And NAL Collaborate On A New Small Turbojet For UCAV Applications

India has long felt the need to develop domestic jet engine capability. Apart from the PTAE-7 turbojet developed by Hindustan Aeronautics Limited’s (HAL’s) Engine and Test Bed Research and Design Centre, which is used to power the Lakshya pilotless target aircraft, it however does not have any other indigenous design that has reached maturity yet. While the flagship fighter-class ‘Kaveri’ low-bypass turbofan engine program being developed by DRDO’s Gas Turbine Research Establishment (GTRE) is some distance away from delivering flyable examples, a few small jet engine development efforts are currently underway by entities looking to power unmanned aerial systems (UAS) being developed by them. The latest among them being the small gas turbine jet engine (SGTJE) collaborative project by DRDO’s Research Centre Imarat (RCI), Hyderabad and the Propulsion Division of the National Aerospace Laboratories (NAL), Bengaluru.

SGTJE is envisaged to be a 275 kgf producing turbojet that according to RCI will power an ‘unmanned combat aerial vehicle’ or UCAV. In recent years, RCI has gone from being a sub-systems ‘feeder’ to other DRDO ‘Missile Cluster’ labs to becoming an all-up system developer of missiles and munitions itself. Its latest foray into UAS development however marks a new phase in its evolution, as this an area that is traditionally the preserve of DRDO’s ‘Aeronautics Cluster’ with the Aeronautical Development Establishment (ADE), Bengaluru usually taking the lead. What is more, RCI is even looking to put together its own turbojet through collaboration with NAL to power this UCAV rather than depending on GTRE for it. Now even if for some reason RCI’s use of the term ‘UCAV’ is a bit of a stretch and that this ‘UCAV’ eventually turns out to be more of a cruise missile (although this is speculation), the development of something such as this is quite unique for the laboratory.

Be that as it may, RCI seems keen to leverage both the specific design capabilities of NAL’s Propulsion Division as well as the latter’s test facilities for small gas turbine engine components to make SGTJE a reality. In the first phase of their collaboration for SGTJE, the idea is to carry out:

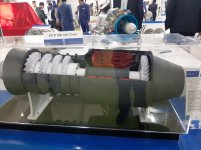

‘detailed design of a turbojet engine of 275 kgf class as per RCI specification and development drawings for components and prototype engine for ground tests considering flight mounting, fuel flow control, pyro starting, alternator and QT/AT testing requirements in participation of RCI. Efforts are to be made by RCI/NAL to realize components for functional testing based on preliminary design to verify the design analysis before closure of the present project. Based on the functional testing & design analysis, prototype engine and componentsdrawings are to be finalized for ground testing.’

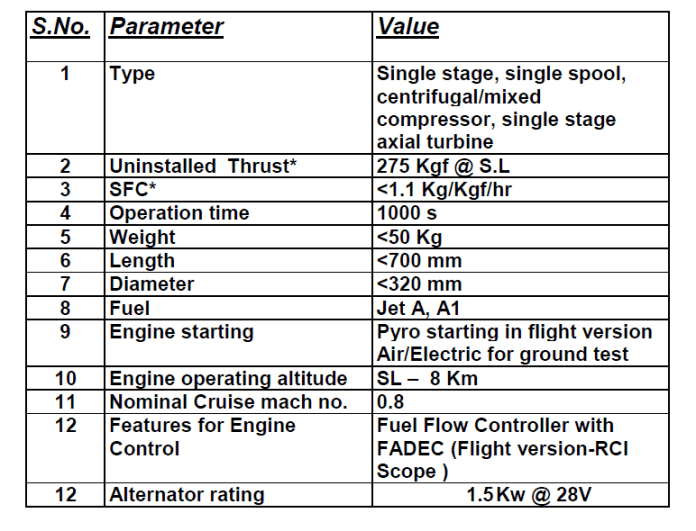

The broad parameters for the SGTJE are given below:

Source: RCI, DRDO

With the requirements specified above in mind, NAL’s Propulsion Division will assist RCI in the following:

‘Detailed design of turbojet engine is to be carried out meeting RCI specifications and qualification/acceptance requirements for airborne engine start for UCAV applications. Based on the literature survey & engine cycle analysis, engine configuration will be arrived at, using centrifugal/mixed flow compressor and axial turbine. After configuring the engine, the components like compressor, combustor, turbine, nozzle, bearings & seals, and rotor dynamic design and analysis will be carried out to meet the design and

qualification requirements. Based on the components structural & CFD

analysis, design optimization & redesign will be carried out.’

The collaboration however does not cover design of SGTJE’s air intake, its pyro cartridge for starting or its alternator. Design & development of the flight version of SGTJE’s fuel flow controller (FFC) with FADEC & alternator, and its air intake are things that RCI will do by itself. Once the detailed design of SGTJE is realized, the second phase of RCI’s collaboration with NAL for it will commence leading to the ground testing of a SGTJE prototype at a NAL test rig. For the initial ground testing, the inbuilt facility Fuel Flow Control at the NAL test rig will be used.

Saurav Jha is the Editor-in-Chief of Delhi Defence Review. Follow him on twitter @SJha1618

Very clean combustion:

Very clean combustion: