To be honest there are few things we should consider in terms of semicondutors.

Why do we want to have our own semiconductor

industry at scale?

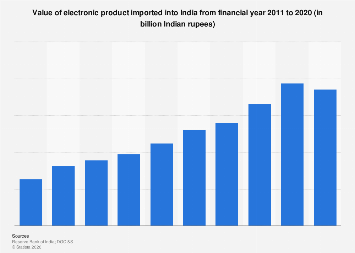

1. To reduce our import bill? There are other ways.

- May be we can improve our export account?

2. To gain strategic freedom from getting bugged semiconductors / denial regimes? Not really needed, atleast at the taiwanese scale.

- For vast majority of semi-conductors used in sensitive area like defence etc can be fabricated on 1998's fabrication technology (180 nm): Things like controllers, memory etc.

- There are niche areas like Radar which actually requires specialized semiconductor processes based on GaAs and GaN instead of silicon as semiconductor. These are low volume high cost products which can be manufactured without market price constrains, so again, you don't need multi billion dollar investment there.

- Even in areas which use modern high performance compute devices for AI applications, the inference part of AI is actually tame in its requirement for computation and is often optimized for lowering compute requirement still. Remember, improvements in semiconductor often saturate by twice or thrice in each generation (Even at Moore's law 18 months for 1.5x), while improvement in software like algorithms can have 10x, 100x, 1000x from one implementation to another (Compare RCNN(x), Fast RCNN (10x), Faster RCNN(100x) and YOLO (1000x) source :

R-CNN, Fast R-CNN, Faster R-CNN, YOLO — Object Detection Algorithms).

- Sensors? Again it is not really required to have 8 nm process. 180-90 nm process is enough.

- Supercomputers? Yesterday's super computers are todays workstation with GPUs. Commodity hardware which is seldom denied.

3. Employment? Not really. Semiconductor manufacturing is not a source of job. Not anymore. May be PCB fabrication might be a better job provider industry.

- Chip manufacturing has become almost a very sublime art of automation. Jobs are far and few.

4. Enabling innovation else where?

- Innovation and value addition these days is a lot more concentrated in software. To give you an example, the interconnect in modern CPUs and motherboards are much more defined by software than by hardware. In storage, SSD have a lot of value derived from its controller algo than just the semiconductor.

- Renting exotic hardware as commodity is becoming more common. You can rent cloud servers with FGPA and exotic high performance GPUs.

- Again for a number of applications, having the best and the biggest fabrication tech is not needed.

The upshot is :

Having the greatest and frontline fabrication technology is not really needed. Its a low margin business. The areas where we can focus are :

1. Solar cells : This is a totally different niche and it does not require SAME type of investment as a top of the line chip process. We should invest a lot in it because it is actually a purely capital industry. Its products produce electricity. And for India it is a boon as sunshine is all we have got. All sun no oil.

2. LEDs : Again, not the top of the line fabrication process needed neither it is as expensive. It is a cost saver industry.

3. Chip packaging : It is needed for all chips and it is much less money intensive. After all if village idiots like Malaysia can do it, how hard it can be?

4. PCB fabrication: While world is going towards SoC, PCB will still be needed.

5. UltraCaps and Energy storage : This is another specialized type of electronic manufacturing with applications in electric vehicles, weapons, drones, lasers.